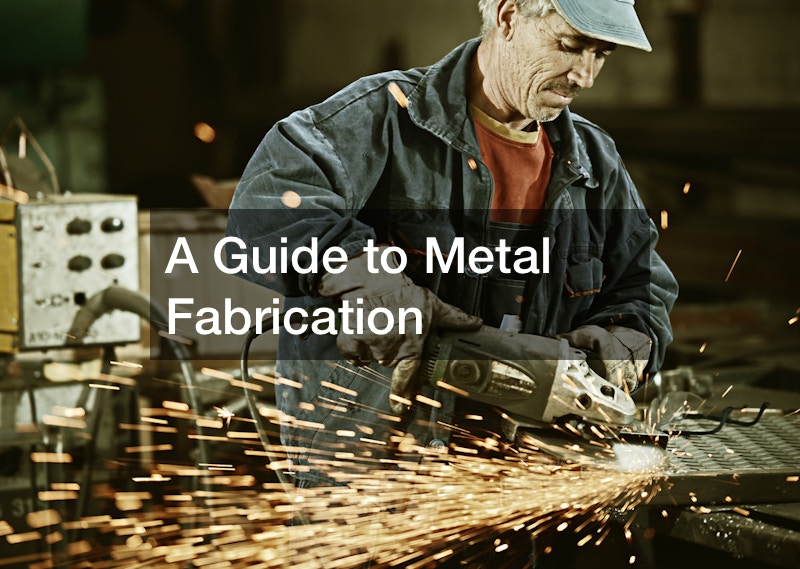

The process of metal fabrication involves cutting, shaping, and assembling metal materials to create a wide range of products. From structural components for buildings to intricate machine parts, fabrication plays a crucial role in modern manufacturing. This guide will explore the basics of fabrication and its importance in various industries.

The first step in fabrication is cutting the metal to the required size and shape. It can be done using tools like saws, shears, or lasers. Once the metal has been cut, it may need to be shaped using bending or forming techniques. This can involve using specialized equipment, such as hydraulic presses or rollers, to create the desired shape.

After the metal has been cut and shaped, it is often assembled using welding or fastening techniques. In welding, you join two or more pieces of metal by melting them together with heat and pressure. On the other hand, fastening involves using screws, bolts, or other mechanical connectors to hold the metal pieces together.

Fabricating metals is essential in a wide range of industries, including construction, automotive, aerospace, and manufacturing. In construction, fabrication is used to create structural components, such as steel beams or columns, while in the automotive industry, it is used to create body panels and engine components.

Whether creating custom components for a construction project or manufacturing specialized parts for a machine, metal fabrication is crucial in numerous industries, making it a vital aspect of the modern economy.

.